Manufacturing Execution System

(MES)

What is MES ?

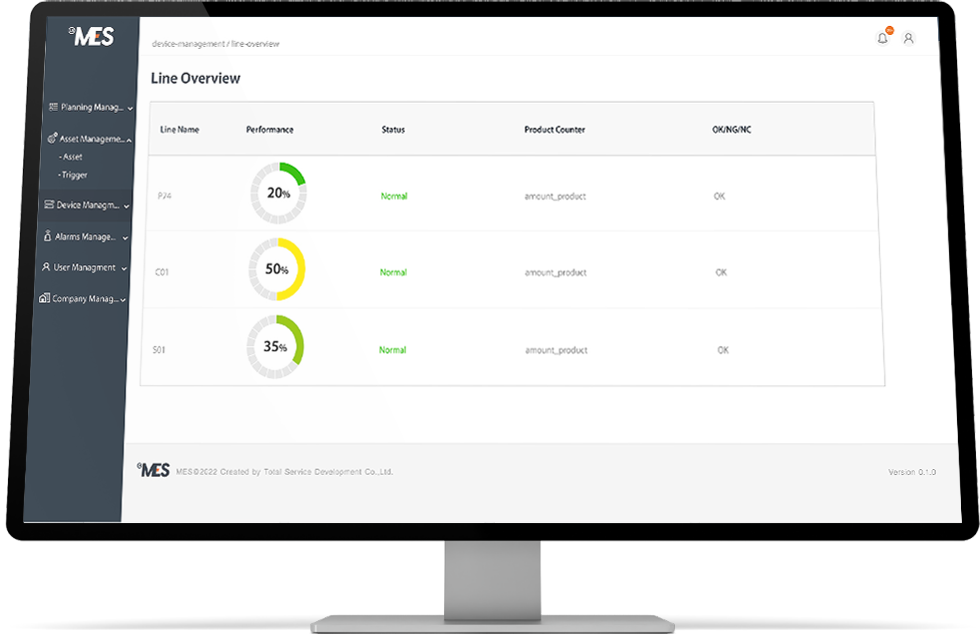

MES: is a system that collects the differential of the machine in production. The data obtained from reading the value

from the sensor of the machine or the sensor that we imported to install in order to useful information for production

The information obtained will be used to monitor, inspect, control and collect data in the production

process in the factory in real-time, from planning to production until the output is obtained.

The main objective of MES Software is to verify that the production process within the factory is in accordance

with the plan or not. including collecting information about the use of machines How much is used in order to compare

with the efficiency of the machine whether it can be produced according to efficiency or not. And can it increase

productivity better? Although the production process in the factory is very complex.

How MES Work ?

MES is a system used to monitor the status of production. By referring to the production plan of the ERP or bringing the production plan from the ERP to be re-planned in more detail in the MES system again to match the existing machines, manpower and raw materials. All of these are the status of production based on WO (Work Order) and WIP (Work In Process). The result will increase the efficiency of production in many aspects.